A vacuum oven gives safe and fast drying of flammable solvents and heat-sensitive materials. Also avoiding deposit buildup, these ovens normally contains stainless steel chambers for sturdiness and stays cool on the exterior throughout use. They have a huge range of utilization including food, books, pharmaceuticals, plastics, chemicals etc. The majority of drying ovens come outfitted with raged glass viewing panes so that the material can be continuously and safely observed. You can finish drying with a traditional oven, however the same is not secure for all objects and can take too much time. An accurate vacuum oven has small warm-up and speedy drying times, and offers the customer a high-level of warmth control.

Common features of vacuum oven

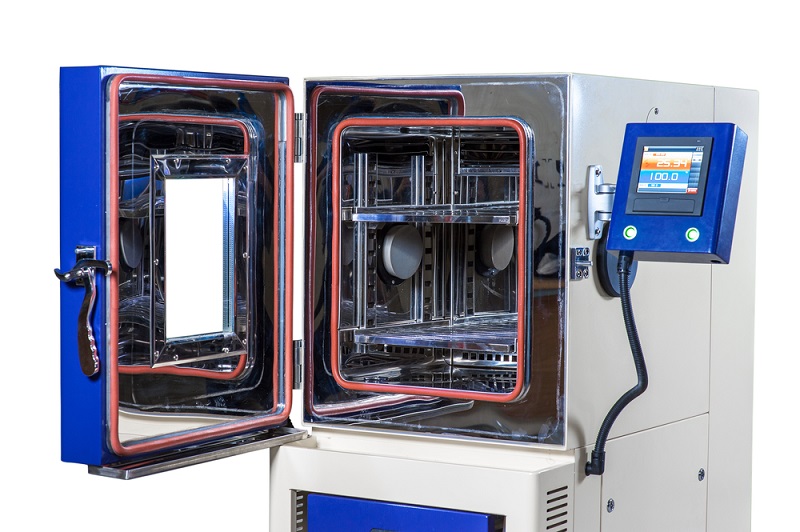

The vacuum oven is utilized for scientific reasons since it has gears, preferably appropriate for laboratory and big scale reasons. Below are the common features of vacuum oven:

- It contains racks, carts, and shelves

- It also has a detonation proof assembly.

- It has logging, recorder, alarms, and timer options

- It contains a cooling scheme.

Types of vacuum oven

There are several kinds of vacuum ovens available in the market. Here are the most common types of vacuum ovens:

- Squaroid Vacuum Oven system – it has the ability to control the temperature up to 220 C. The built-in-high-limit thermostat protects the overheating of the items. This type of oven features vacuum fitting, which aid in venting and purging of hydraulic thermostat and inert gases, which manages temperature. This oven is also needed for brazing, sterilizing, baking, heating plus reasons in the industries.

- Multi-Module Vacuum Oven– this is perfect for packaging of the products that need vacuum bake out. This type of oven assists in inert gas seam-sealing, temperature curing, and laser welding. The vacuum ovens, therefore, cater diverse facilities for the scientific purposes, laboratories, and industries.

Some important facts about vacuum ovens

Ovens are made of different types of refractory or high-temperature materials to grasp the course-material and capture the temperature without breaking down throughout the numerous months that they generally run.

Heating Sources for Vacuum-Ovens

Induction, resistance or electric, and arc are some of the common resources for vacuum ovens. In an arc pattern an arc among metal and graphite electrodes produce heat.

- Both alloy and carbon steels are generated in scrap and electric arc ovens instead of molten metal is utilized as the base object.

- In resistance heated or an electric unit, the temperature resource is powered by current – usually using accessible plant voltages.

- Induction is an extensively used method for the surface congealing of steel. The modules are heated through an irregular magnetic field to a heat in or over the alteration range perused by instant quenching. Controller-types can be programmable or distinct set point.

Configurations of Vacuum Ovens

Vacuum oven’s configurations include truck-in or walk-in, vertical, cabinet or bench, and muffle or tube. A muffle or tube oven is an oven wherein the temperature is oblique; the object to be heated is placed in an obstinate pot heated from the exterior. Bench or cabinet oven illustrates little batch gear normally escalated on primary stands. Batch ovens are usually suited for processing amounts of materials in one batch. Vertical unit configuration saves space.

This type of oven is vertical rather than horizontal. This usually needs larger height clearances. Truck-in or walk-in ovens illustrate bigger size batch gear, usually with double doors plus integral shelves, carts etc. Batch ovens are usually suitable for processing bigger amounts of product in one batch.

If you still want to know more than visit here and get more information about vacuum oven.